Cooling

The cooling system in dry type oil-free rotary screw compressors normally consists of an air cooler after each stage and an oil cooler. These may be water-cooled or air-cooled radiator type.Water-injected oil-free rotary screw compressors use the injected water to remove the heat of compression. The injected water is then removed from the discharged compressed air by a conventional moisture separation device.

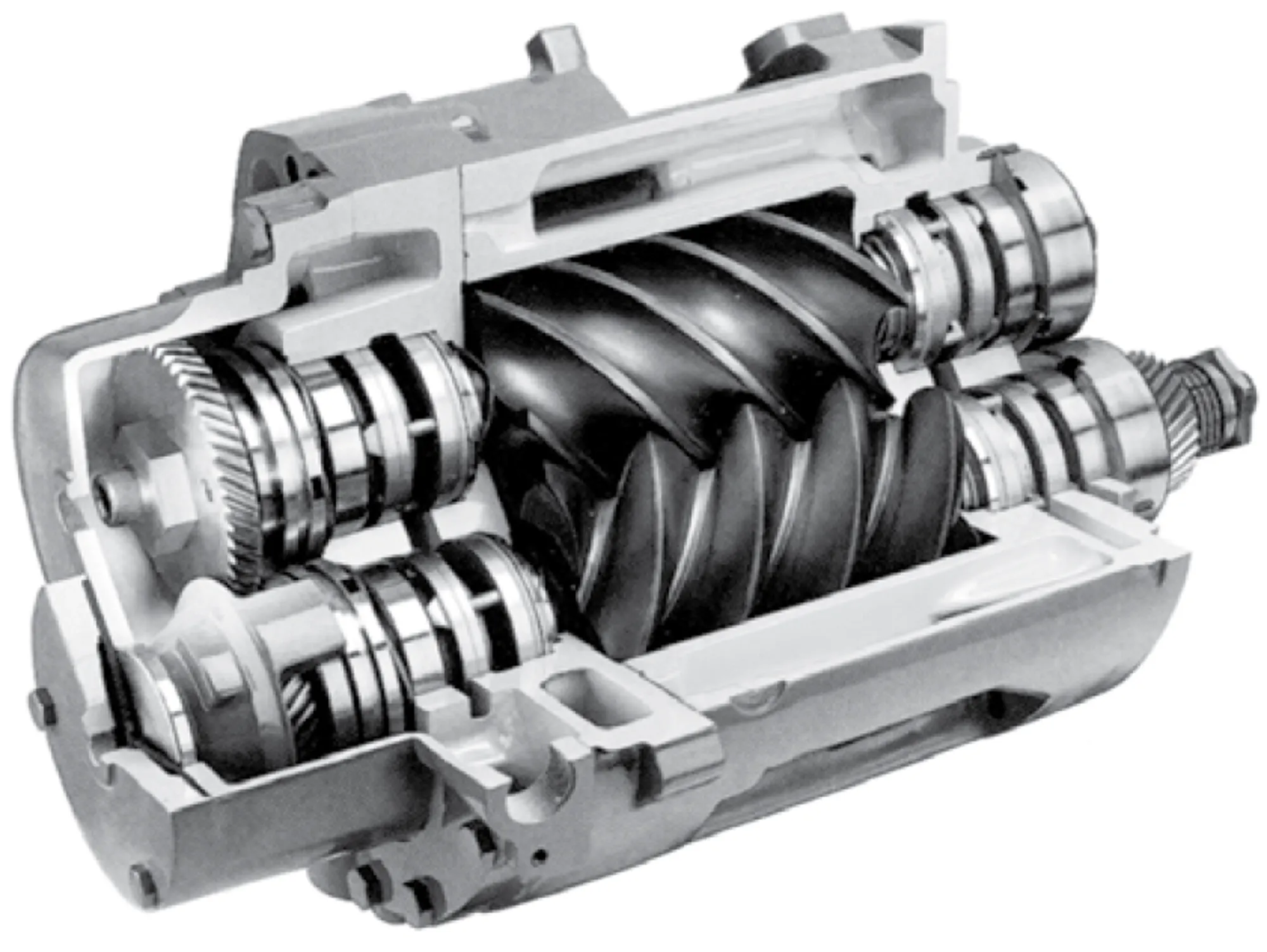

Oil-Free Rotary Scroll Compressors

Oil-free by design, the rotary scroll compressor has become a popular compressor as a domestic air conditioning refrigerant compressor. More recently, it has been introduced to the standard air compressor market in the lower end of the horsepower range of rotary air compressors.

The operating compression principle involves two intermeshing spirals or scrolls, one scroll being stationary and the other orbiting in relation to the stationary scroll. Air entering through the suction port in the stationary scroll fills the suction chamber, then the portion of the compression chamber at an intermediate pressure is sealed by adjacent portions of the two scrolls. As orbiting continues, the space occupied by the air becomes progressively reduced and moves progressively toward the discharge port in the center of the stationary scroll.

Lubrication

There is no metal to metal contact between the scrolls, eliminating the need for lubrication in the compression chamber and ensuring oil-free air delivery from the scroll compressor.

Cooling

Current models are air cooled, and noise levels with a sound attenuating canopy are extremely low, in the range 52 - 59 dBA at 1 meter, in accordance with the CAGI/Pneurop test code.